Manufacturing Solutions for the Circular Economy

The plastics industry has a dirty secret: while we can effectively recycle more kinds of plastic than ever before, very little plastic actually gets recycled. Just 2% of plastics are recycled into new products, according to experts. The rest ends up in landfills, is released into the environment, or burned. And what does get recycled is often transported great distances (like across the Pacific) where it’s converted to plastic pellets, then transported again (back across the Pacific) to be turned into products—a journey that brings a steep emissions price tag.

The Curb-to-Market Challenge was created to spark solutions to this problem in the form of not just products, but full manufacturing systems that could turn solid waste into new products in one location. As challenge founder Chris Graff says, “Why can’t we take some of this recyclable trash, manufacture something here instead, and then sell into this market?”

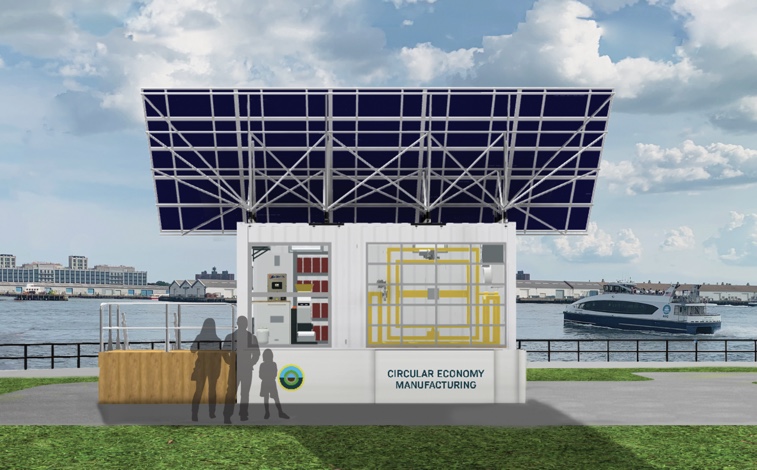

The portable MicroFactory concept from Anthropocene.Design’s Barent Roth was one of two winners of the challenge. The idea was to fit a complete system capable of turning plastic waste into new products in a recycled shipping container, and power the system using only solar energy.

“We practice Whole Systems Thinking and try to solve multiple problems at once,” Roth says. “Chris’s competition gave us the opportunity to synthesize various sustainable strategies into one simple scalable manufacturing concept.”

Barent Roth introduced his portable MicroFactory during his AU 2020 Theater talk. The system turns household plastic waste into new products using solar power.

Once is not enough

As both a designer and an educator, Roth has been specializing in the possibilities and practicalities of circular design for his entire career. Instead of designing products to be used once, as though resources were unlimited, circular design principles strive to create products that can be perpetually reused in a closed-loop material cycle. Sometimes referred to as cradle to cradle, circular design posits that it’s a mistake to view a process as having waste—everything should be considered resources for something else. Roth provides an introduction to the concepts and goals of circular design in his AU article, Designing for the Circular Economy.

Roth’s BikeShare Helmet was a winner of the Cradle-to-Cradle Design Competition, he was the founder of Testing Our Waters, and he served as executive director of SustainableWorks. These days, in addition to teaching courses in design and product life cycle analysis at The New School-Parsons, Roth has joined forces with Chris Graff, founding Circular Economy Manufacturing to turn the MicroFactory concept into a functioning business.

Production during the pandemic

Roth and his team worked in Fusion 360 to design the MicroFactory as well as the products it will make, so they could continue collaborating throughout the 2020 lockdown. “Fusion 360 enabled us to work on the same model in real-time from different cities,” Roth says. “Between that and my little 3D printer for prototyping our products, we had what we needed.”

The first MicroFactory is currently being assembled on Governors Island, a public space just off the coast of Manhattan, which aims to become a hub for climate change research and education. And the first product the MicroFactory will make from waste generated in New York City? A collection bin for composting food scraps, designed to fit in any refrigerator.

"In a circular economy, you aim to keep all materials flowing in two cycles: the Technical and the Biological," Roth explains. "The Technical Cycle is for recycling metal, glass, and plastic. The Biological Cycle is for composting food, plants, and wood. Our manufacturing process streamlines the Technical Cycle while our first product supports the Biological Cycle." In the future, Circular Economy Manufacturing aims to make other consumer products, such as children’s chairs, as well as products for municipal use, such as traffic cones and bollards.

“There have been some pandemic delays which have impacted the assembly of the MicroFactory—the see-through roll-up door added weeks,” says Roth. “Our shredder had the greatest delay, but it’s understandable when you learn that the supply company started making ventilators.” In July, the team will install the solar panels that power the shredder and heat the roto-molder. “Traditional roto-molding is done in a giant fossil-fuel oven,” Roth says. “We want to show that you can manufacture using locally collected renewable energy.”

Open for business

As they get the first unit up and running, Roth and team are preparing to launch a fundraising campaign on Kickstarter, while also seeking equity investors. The business model involves leasing the MicroFactories to communities large and small, and also selling the products they make. “This is something that could scale globally,” Roth says. “Large urban areas can use them, since cities generate so much waste. But it could also be valuable in remote and disadvantaged communities. Since it’s a self-enclosed system, you don’t even have to be on the power grid to use it, and it creates green jobs.”

The project has an educational component, too. Visitors to the MicroFactory on Governors Island will get the chance to see what circular design looks like in action (thus, the need for a transparent roll-up garage door). And interested designers have been able to watch the design process, too, as the team has been sharing their Fusion 360 model every step of the way.

Fusion 360 model for the Next Generation Dual Container MicroFactory.

“We want people to see with their own eyes what is possible when we truly value resources. I’ve been teaching the sustainability of materials and processes to designers for 25 years, and this MicroFactory is a logical extension of that effort,” Roth explains. “We all need to act with a sense of urgency to address climate change and plastic pollution. This is our humble but ambitious attempt to change the way the world makes things.”

Want to know more about Circular Economy Manufacturing and support their work? You can sign up to receive project updates on their website, check out their Kickstarter campaign, and follow them on social media @CircularEconomyMfg.